I did some work on the tractor: I bought new front tires and replaced the front wheel bearings. I also finally got around to tearing off the left brake assembly and replacing a badly damaged seal that was leaking the transmission oil out. The brakes work now that they’re not doused in oil. It will be nice to have the transmission stay full.

I did my first weld with our new welder: reattaching a bracket to the mower deck for the Craftsman.

I also replaced an idler pulley that had seized up and made the tractor undrivable.

On the Case tractor, I’ve been drilling out lug bolts that sheared off from trying to remove the left real wheel.

I also tried fixing up the hand throttle, but I can’t hammer or drill the pin out of the shaft, and I can’t get the shaft to turn

Today was a big day.

The Case tractor was down for a couple months to fix the clutch. The clutch fork partially broke and no longer worked. I scoured eBay and found a replacement. I also scoured eBay to find replacement oil seals for the hydraulic pump. When we tried to put the tractor back together, we didn’t get the hydraulic shaft splines lines up and warped the clutch pressure plate. After two failed attempted to buy a replacement, I finally got one on the third try for $270. This time, we took the access cover off the side of the torque tube and put things back together very carefully, checking frequently as we went, and it worked. Today, we finished putting all the other pieces back on, and we started it up and drive it around. I considered replacing the clutch disc while we had the tractor split, but a replacement is almost as expensive as the pressure plate, so I didn’t.

Next, we need to replace one of the rear wheel rims, which has rusted out. Our neighbor Jon might be able to find one. We also need to fix leaks in the front hydraulic pump and left brake assembly.

Also today, the bees came. The boys worked hard the past few weeks to assemble the beehive, and today we got the nuc. The nuc cost $120, and we’ve spent another couple hundred on the hive and equipment. We probably won’t be able to harvest any honey the first year.

Heather pressure cooked 50 pounds of chicken and 7 pounds of beef this week. She also dehydrated about a quart of celery, carrots, mushrooms, and onions.

We are considering getting rabbits to breed for meat.

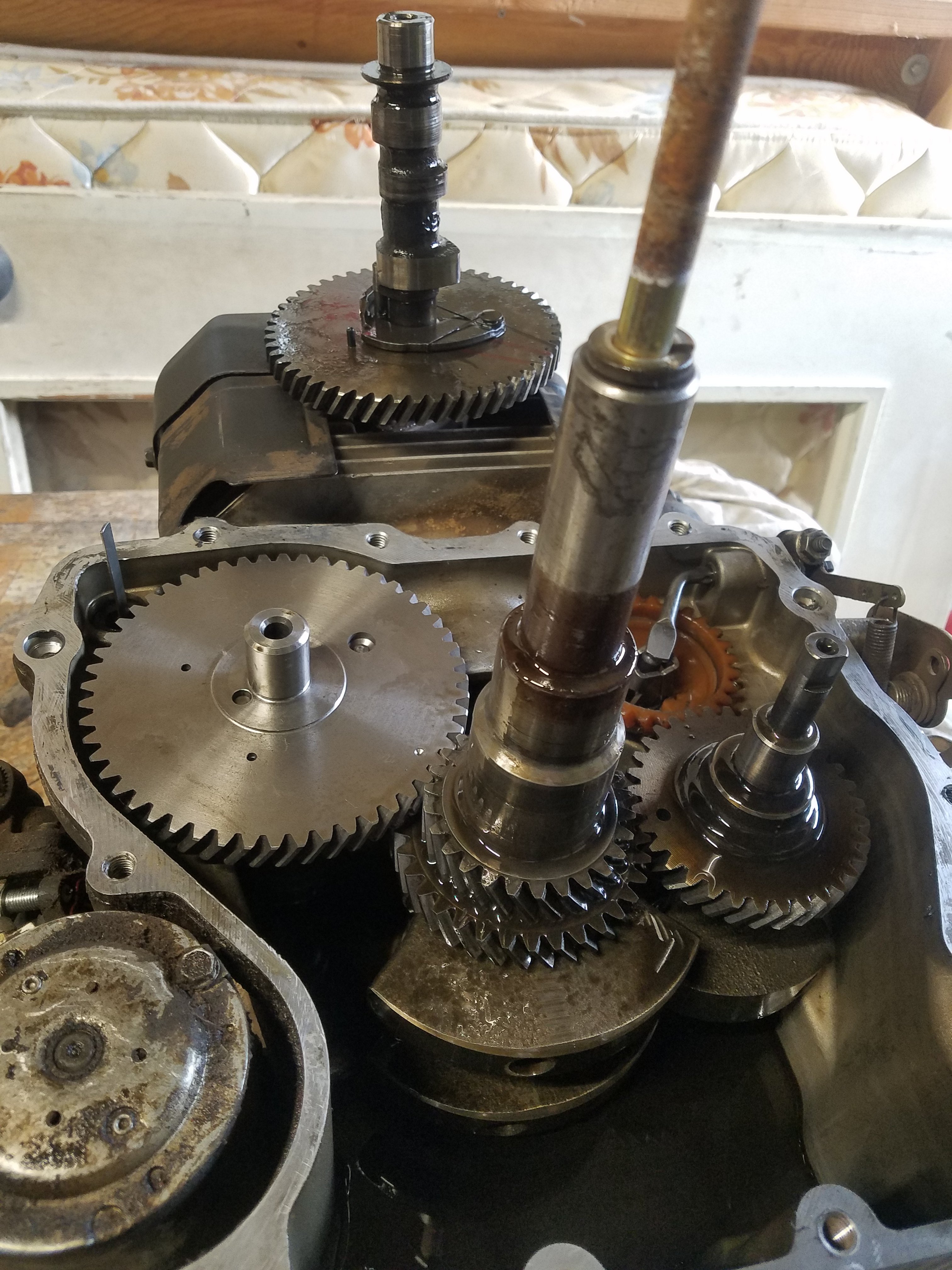

The John Deere riding mower died last fall. It would barely idle, nothing more. We replaced the carburetor, but it didn’t help. It turns out the intake valve wasn’t opening enough. So I took apart the crankcase and checked things out. The camshaft lobe that drives the intake valve was worn down to nearly nothing. The hydraulic lifter was also stuck. So I ordered a new camshaft and lifters for $40. Today I put everything back together, and it runs great!

In the meantime, our neighbor Jon found a two-cylinder Craftsman mower for us. It ran but not well. I ordered a tune-up kit and Isaac helped replace the carburetor, filters (air, fuel, oil), and oil. It’s up and running now as well.

So now we have two riding mowers, a garden tractor, a tow-behind field mower, and of course, the Case tractor. The clutch has gone out on the Case, so we’re clearing space in the barn to bring it in, split it, and fix it.

Yesterday, our friend help us get the town-behind lawn mower that our neighbor gave us running. A kit with a carburetor, spark plug, fuel filter, and air filter was $20. Next I need to buy new wheel bearings for it and for the small tractor trailer.

We changed the oil and spark plug in the Sears tractor.

The Case tractor is not doing so well. The past few weeks, it has been hard to start, which was not a problem before. I replaced the spark plugs today. Most of them were black with carbon. I also topped off fluids. It took about 3 quarts of fluid in the torque tube and a gallon of oil in the transmission. The 3-gallon cooling system took a gallon of coolant. I replaced the engine oil, and there was coolant in the oil. That probably means it has a bad head gasket. Also, yesterday the clutch started to fail. Today I had to use the hand clutch, and even then, I had to turn off the tractor to change gears. One of the back wheels still has a slow leak, too.

I re-routed the temporary pasture fencing on the north side of the barn so that I can access the tractor parking area again. The sheep will probably have that extra pasture area finished off in the next two weeks or so.

The chickens have finished off my kale. 🙁

A few months ago, we got to use a hydraulic log splitter to split a bunch of wood we had gotten from arborists. Today, we stacked it along the west side of the barn, probably about 1.5 cords. We don’t have a woodstove, though.

We also reapplied wood chips around the young fruit trees after adding some landscaping fabric.

The sheep have mowed the entire pasture down to stubble, due to our not implementing paddocks. Heather has installed some temporary fencing allowing them to graze the area north of the barn.

We haven’t gotten any chicken eggs for months. But they don’t have a proper chicken coop in which to lay eggs, nor are we giving them any feed beyond table scraps and what they find in the pasture.

Something happened to the carburetor on the John Deere mower and it will barely idle at full throttle. I fiddled with it a bit, then ordered a new carburetor. At about $15 to buy new, they’re hardly worth trying to troubleshoot.

The Case tractor has a rear left tire that loses air over the course of about a week. I need to see if I can remove the wheel so I can take it to a tire store for repair. Otherwise, it’s probably about $100 for a field service call.

We’re still getting some kale from the garden, but the chickens have been escaping the pasture now that we extended it for the sheep, so the kale isn’t going to last much longer.

I tried in vain to find replacement pins for the quick release mechanism on the tractor loader. Then I remembered, with old things you’re supposed to be able to make your own parts. So I did. Now the quick release works again.

I lifted the old well cover today, and the water was 7 feet below ground level, giving us 16 feet of water.

We got our first picking of blackberries today.

I reinstalled the original oil bath air cleaner on the tractor. I bought a 30-inch long flex radiator hose with a 1-1/2-inch inside diameter to connect from the air cleaner to the carburetor.

We changed the fluids in the tractor: hydraulic fluid in the hydraulic reservoir (topped off), hydraulic fluid filter, hydraulic fluid in the torque tube (drain and refill), gear oil in the steering box, gear oil in the transmission (flushed with diesel), engine oil and filter, and grease in as many grease fittings as we could find. I also topped off the coolant and installed a new radiator cap. The oil in the transmission was like milk, and the oil in the engine was blacker than black. We found a large screwdriver in the transmission.

The tractor came. It’s a 1958/59 Case 310B with an International 2000 loader. We paid $500.